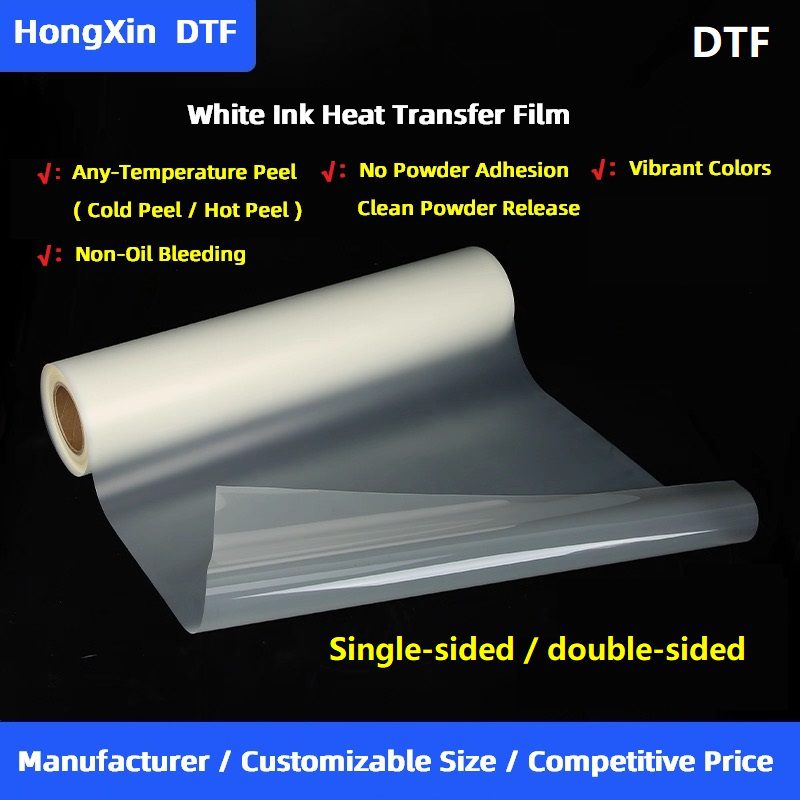

Premium DTF Film

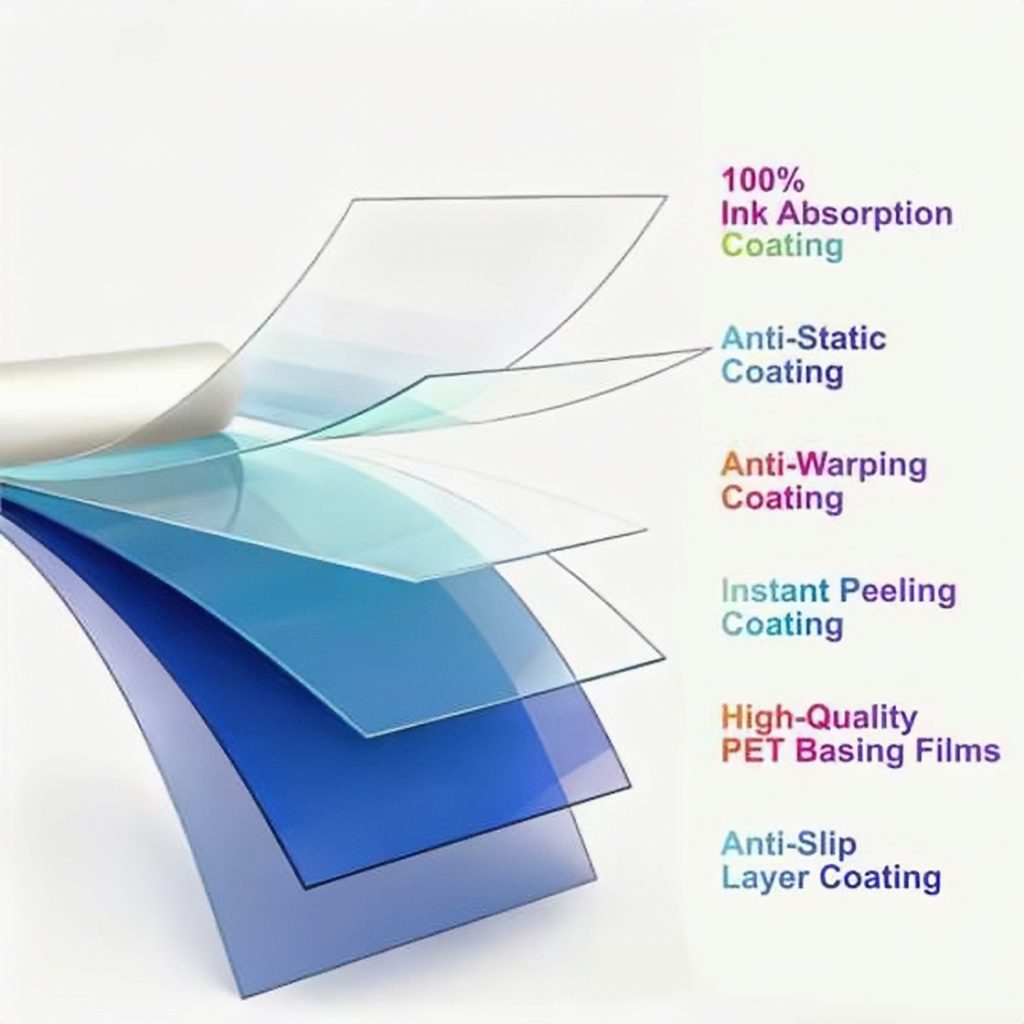

Our PET-based DTF film delivers vibrant colors and excellent ink absorption-enabling high-precision printing and long-lasting, wash-fast graphics on both light and dark textiles.

It also features easy peel-off release, and we offer custom roll sizes to accommodate any production line.

Instant Peeling DTF Film

● Material Type: PET

● Product Type: Rolls

● Roll width: 30cm/60cm/90cm/120cm/180cm (customized )

● Roll length:100m/150m/200m/300m (customized )

● PET base film thickness :75µm (customized )

● Coating thickness (Double-side) :13±5µm

● Anti-static value (Ink-absorbing layer) :10⁶ Ω - 10¹¹ Ω

● Coating Options:

● Single-sided coating, High cost performance,

● Double-sided coating, High adaptability

More Detail

Wide Applications for DTF Film

● T-shirts

● Caps & Hats

● Hoodies & Sweatshirts

● Canvas Bags & Totes

● Shoes & Sneakers

● Pillows & Home Textiles

● Backpacks & Accessories

● Jeans & Denim Wear

● Aprons

● Umbrellas

● And More...

Working Conditions of DTF Film

Compatible consumables can assist in the precision, speed, and stability of your printers to the maximum.

★ Printing Environment

Suitable for DTF powder shakers and desktop DTF printers. Recommended environment: normal temperature, humidity below 50% (to ensure proper drying and powder shaking).

★ Hot-Melt Adhesive Powder

★ Heat Transfer Conditions

Set heat-press temperature between 140–160°C, and press for 10–15 seconds for ideal results.

★ About Storage

DTF Film Transfer Process

Follow these streamlined steps from design through final press for vibrant, durable DTF transfers.

1. Prepare Design: Create your artwork at full resolution.

2. Layout & Print: Typeset and print on DTF film.

3. Apply Powder & Cure: Apply hot-melt powder, shake off excess, and cure until melted.

4. Heat Press: Press at 140–160 °C for 10–15 s.

5. Peel Film: Remove film (hot or cold peel instant).

6. Final Inspection: Check transfer for color and durability.

Pre-Tested DTF Ink & Hot Melt Powder Bundle

We test our films with matching inks & powders to guarantee perfect transfers—one-stop, zero hassle.

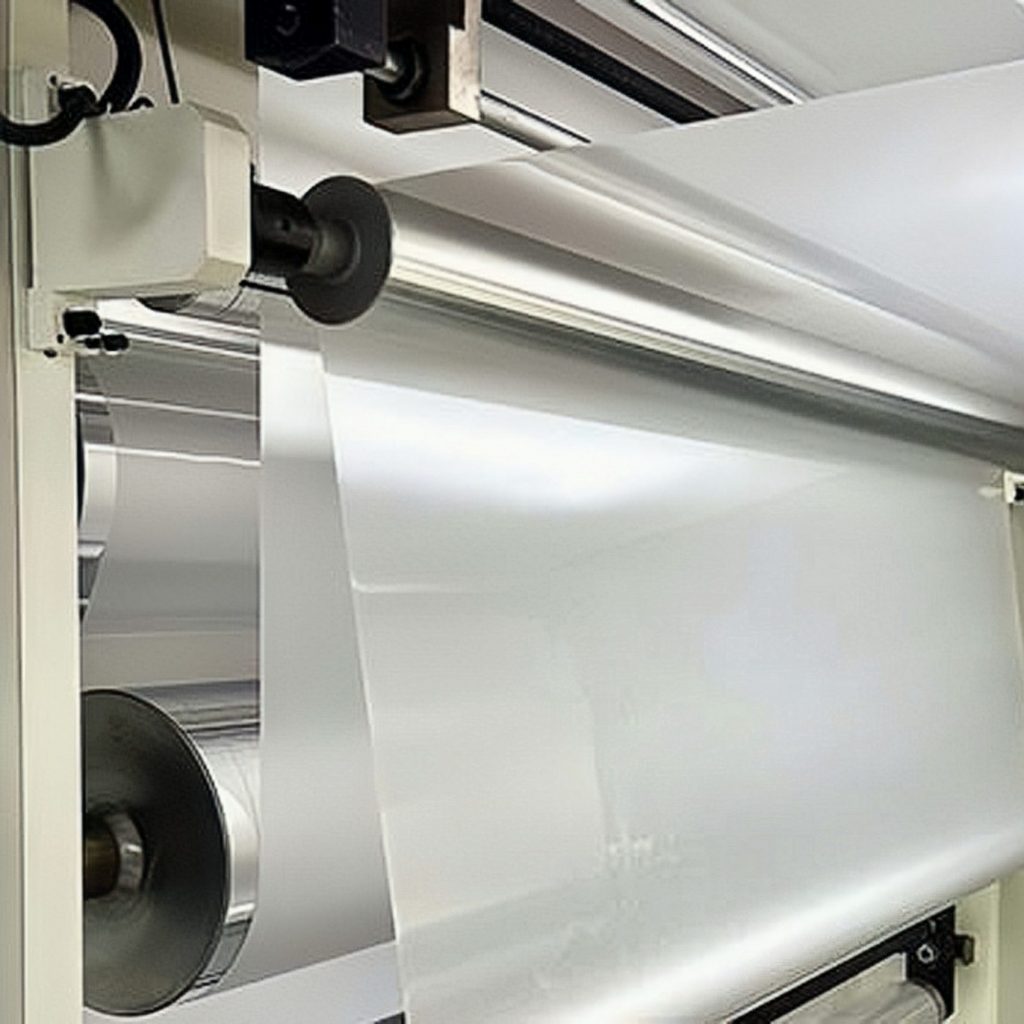

Production Process

Base film

Back coating

Print coating

Rewinding

Semi-product

Final Cutting

Warehouse area

Custom Packaging

Related Products

DTF Film

High-definition digital prints with long-lasting adhesion on cotton, polyester, and blends.

UV-DTF Film

Create durable, vibrant, and long-lasting decals and transfers for hard, non-porous surfaces.

TPU 3D DTF Film

3D sharp relief digital prints with long-wearing adhesion on cotton, polyester, and blends.

3D Embroidery Film

3D realistic embroidered texture prints with secure adhesion on cotton, polyester, and blends.

HongXin DTF

We deliver consistent quality, fast lead times and one-stop solutions for global partners.

Company

Contact

+86 192 6065 1291

sales@hongxindtf.com

Daliang, Shunde Foshan , Guangdong , China