Premium TPU 3D DTF Film

Our TPU-based 3D DTF film delivers striking three-dimensional textures and superior ink adhesion, enabling high-definition printing and stretch-resistant, wash-durable graphics on both elastic and rigid textiles.

It also boasts exceptional scratch resistance and yellowing resistance for long-term vividness, and we provide custom roll dimensions to fit any production workflow.

TPU 3D DTF Film

● Material Type: TPU-based 3D DTF Film

● Product Type: Rolls

● Roll width: 30cm/60cm/90cm/120cm/180cm (customized sizes available for bulk orders)

● Roll length:100m/150m/200m/300m (customized lengths supported to match production line demands)

● TPU 3D base film thickness:90µm (customized thickness range: 80-120µm optional)

● Anti-static value (Ink-absorbing layer) :10⁶ Ω - 10¹¹ Ω

● 3D texture height after hot pressing:5-15µm (adjustable based on customer’s 3D effect requirements)

● Stretch recovery rate:≥95% (suitable for elastic textiles like sportswear, swimwear)

More Detail

Wide Applications for TPU 3D DTF Film

● Sports Apparel & Athleisure Products

● Headwear & Bag Accessories

● Footwear Products

● Sports Protective Gear

● Children's Products

● Home Textiles

● Cultural and Creative Gifts

● Automotive Interior Accessories

● Daily accessories

● Sports equipment

● Industrial accessories

● And More...

TPU 3D DTF Film Transfer Process

Follow these streamlined professional steps from design through final press to achieve vivid, 3D-textured, and stretch-durable TPU3D DTF transfers, suitable for elastic and rigid substrates.

1. Prepare Design: Create artwork at full resolution, set 3D texture thickness to 5–15 μm (match the pre-coated adhesive layer’s compatibility to ensure vivid 3D effect).

2. Layout & Print: Typeset and print on the TPU 3D texture layer (ensure uniform ink coverage to avoid uneven 3D texture; use special white ink + color ink for better adhesion).

3. Peel Release Liner: Before heat pressing, peel off the PET release liner smoothly to expose the pre-coated adhesive layer (the slight viscosity helps pre-position, preventing displacement during pressing).

4. Heat Press: Press at 150–170 °C with 0.3–0.5 MPa pressure for 15–20 s (adjust time appropriately: +3–5 s for thick elastic fabrics; -2–3 s for thin rigid substrates).

5. Cool & Set: After heat pressing, let stand at room temperature for 30–60 s to cool and set (no need to peel any film again; cooling ensures the hot-melt adhesive cures completely and the 3D texture stabilizes).

6. Final Inspection: Check the transfer effect—verify color vividness, 3D texture integrity, adhesion (no peeling or edge lifting) and stretchability (stretch the substrate 2–3 times, no cracking).

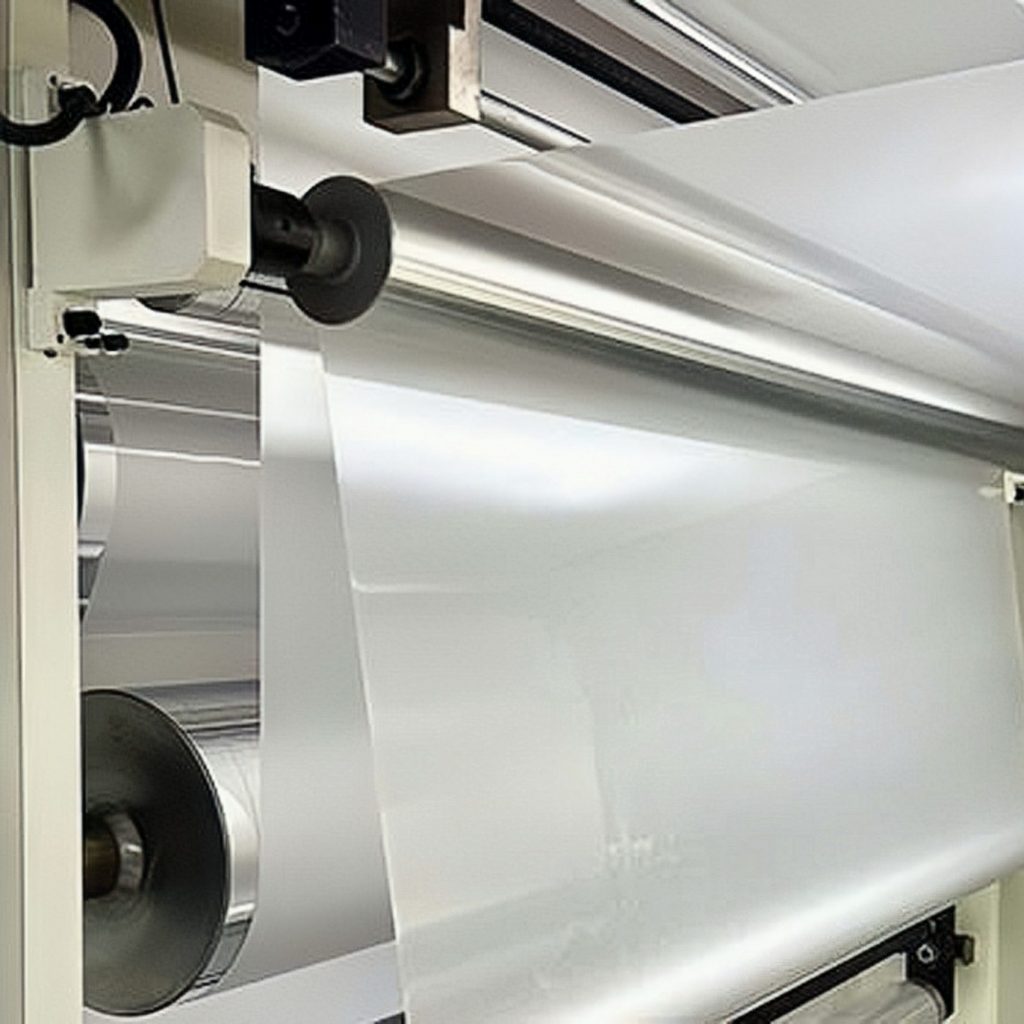

Production Process

Base film

Back coating

Print coating

Rewinding

Semi-product

Final Cutting

Warehouse area

Custom Packaging

Related Products

DTF Film

High-definition digital prints with long-lasting adhesion on cotton, polyester, and blends.

UV-DTF Film

Create durable, vibrant, and long-lasting decals and transfers for hard, non-porous surfaces.

TPU 3D DTF Film

3D sharp relief digital prints with long-wearing adhesion on cotton, polyester, and blends.

3D Embroidery Film

3D realistic embroidered texture prints with secure adhesion on cotton, polyester, and blends.

HongXin DTF

We deliver consistent quality, fast lead times and one-stop solutions for global partners.

Company

Contact

+86 192 6065 1291

sales@hongxindtf.com

Daliang, Shunde Foshan , Guangdong , China