Premium 3D Embroidery Film

Our PET-based 3D Embroidery Film delivers lifelike 3D embroidery textures and excellent UV ink compatibility, enabling high-precision simulated embroidery patterns and wash-resistant, abrasion-resistant graphics on both textiles and rigid substrates like leather and canvas.

It also boasts eco-friendly solvent-free properties and excellent shape retention for long-lasting dimensional stability, and we offer custom roll sizes to accommodate diverse production demands.

3D Embroidery Film

● Material Type: PET

● Product Type: Rolls

● Roll width: 30cm/60cm/90cm/120cm/180cm (customized sizes available for bulk orders)

● Roll length:100m/150m/200m/300m (customized lengths supported to match production line demands)

● PET base film thickness:70µm (customized thickness range: 60-90µm optional)

● Coating thickness (Single-side 3D embroidery texture layer):20±5µm (optimized for UV ink curing and 3D texture forming)

● Anti-static value (UV ink compatible layer):10⁶ Ω - 10¹¹ Ω

● 3D texture height after UV curing:8-25µm (adjustable based on customer's embroidery effect requirements)

More Detail

Wide Applications for 3D Embroidery Film

● Clothing Industry

● Footwear & Luggage Industry

● Home Textiles Industry

● Cultural & Creative Gift Industry

● Enterprise Customization & Branding Industry

● Automotive Interior Decoration Industry

● Daily necessities

● Industrial accessories

● And More...

3D Embroidery Film Transfer Process

Follow these streamlined steps from design through final press for lifelike 3D embroidery textures and durable transfers, suitable for textiles, industrial accessories and rigid substrates.

1. Prepare Design: Create your artwork at full resolution, set 3D texture height parameter (8–25 μm) to match simulated embroidery effect.

2. Layout & Print: Typeset and print on the 3D embroidery texture layer with UV DTF special ink (ensure uniform ink layering for vivid 3D effect).

3. Post-Print Inspection: Check the printed film for complete curing of ink and initial formation of 3D texture (no sticky surface, clear texture layers).

4. Heat Press: Press at 120–150 °C for 15–20 s (0.2–0.4 MPa pressure; adjust time for industrial accessories with rough surfaces).

5. Peel Film: Cold peel after standing for 20–30 s (peel PET release liner smoothly to protect 3D embroidery texture from deformation).

6. Final Inspection: Check transfer for 3D texture integrity, color vividness, adhesion (no peeling) and wear resistance (for industrial accessories).

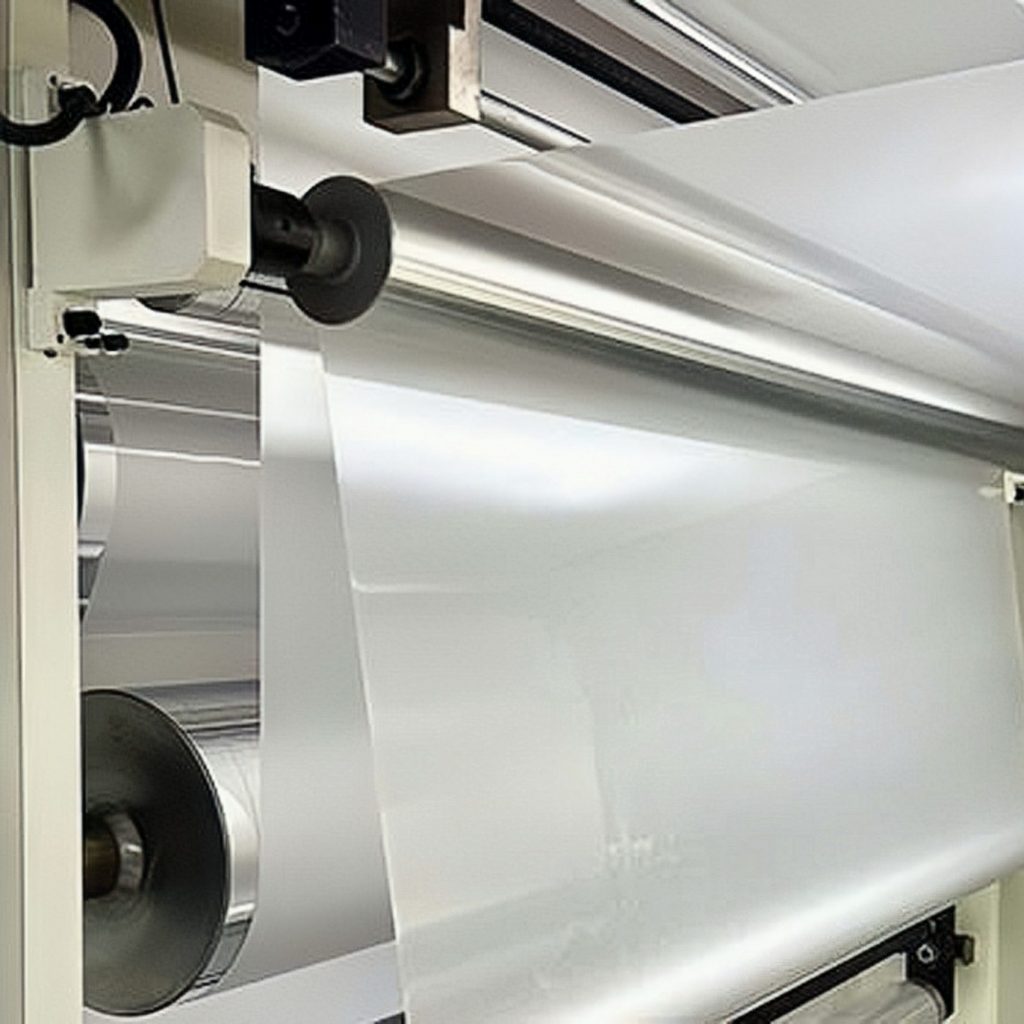

Production Process

Base film

Back coating

Print coating

Rewinding

Semi-product

Final Cutting

Warehouse area

Custom Packaging

Related Products

DTF Film

High-definition digital prints with long-lasting adhesion on cotton, polyester, and blends.

UV-DTF Film

Create durable, vibrant, and long-lasting decals and transfers for hard, non-porous surfaces.

TPU 3D DTF Film

3D sharp relief digital prints with long-wearing adhesion on cotton, polyester, and blends.

3D Embroidery Film

3D realistic embroidered texture prints with secure adhesion on cotton, polyester, and blends.

HongXin DTF

We deliver consistent quality, fast lead times and one-stop solutions for global partners.

Company

Contact

+86 192 6065 1291

sales@hongxindtf.com

Daliang, Shunde Foshan , Guangdong , China